Inventory Management and Economic Ordering Quantity (EOQ):

Inventory is current asset; inventories are purchased for sale or production for sale. Optimum level of inventory is good current asset management.

1. Types of Inventory

Inventory is divided into 3 categories:

-

- Raw Materials

- Work in Progress (WIP) or Unfinished Goods

- Finished Goods

2. Associated Costs of Inventory

There are 2 basic costs associated with inventory as follows:

a. Carrying Costs

Carrying costs of inventory include the following items:

-

- Storage

- Insurance

- Financing costs

- Shortages

- Damages

- Write-offs of obsolete, unsalable stock

b. Ordering Cost

Ordering costs of inventory include the following items:

- Purchasing

- Systems

- Receiving

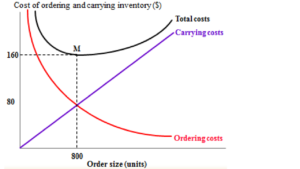

Optimum level of inventory will satisfy customer demand or production requirements while minimizing ordering and carrying costs.

How much do you order at one time?

It is based on the following factors:

- Forecast sales or usage

- Cost of placing and receiving order

- Inventory carrying costs

- Economies of scale

-

Inventory Management Techniques

We manage inventory for two techniques- economic ordering quantity and the just-in-time model.

a. Economic Ordering Quantity (EOQ)

The following features are for economic ordering quantity (EOQ):

- EOQ is the optimal (best) amount for the company to order each time.

- EOQ occurs at the low point on the total cost curve.

- EOQ is the order size that is total carrying costs equal total ordering costs (assuming no safety stock).

Safety Stock:

Safety stock term is a level of extra stock that is maintained to mitigate risk of stockouts due to uncertainties in supply and demand.

The following features are for safety stock.

- Extra inventory the firm keeps in stock in case of unforeseen problems.

- Minimum level of inventory planned.

- Management decision based on risk of stockout.

- Safety stock is designed to minimize stockout.

b. Just-In- Time Inventory Systems

Common Features for Just-In-Time (JIT) inventory systems are as follows.

- Minimum levels of inventory

- Orders in small lot sizes

- Computerized order and inventory systems

- Small number of suppliers

- Quality control programs

- Electronic data interchange

- Short delivery times

Potential Benefits for Just-In- Time Inventory Systems:

- Lower carrying costs

- Automatic ordering

- Lower quality control costs

- Elimination of waste

- Fewer accounting errors